ESCO Gear Couplings

CHARACTERISTICS OF THE ESCO GEAR F SERIES COUPLINGS

The Escogear coupling is a torsionally rigid, grease filled coupling consisting of two hubs with external multicrown – and two flanged sleeves with straight internal teeth. The flanged sleeves are bolted together with high strength corrosion protected fitted bolts and nuts. The sleeve is at the opposite side of the flange executed with an endcap (internal for small and screwed for big size couplings) in which the o-ring is located for sealing purposes. The Escogear coupling has been designed to transmit the torque between these two flanges through friction avoiding fretting corrosion between these faces.

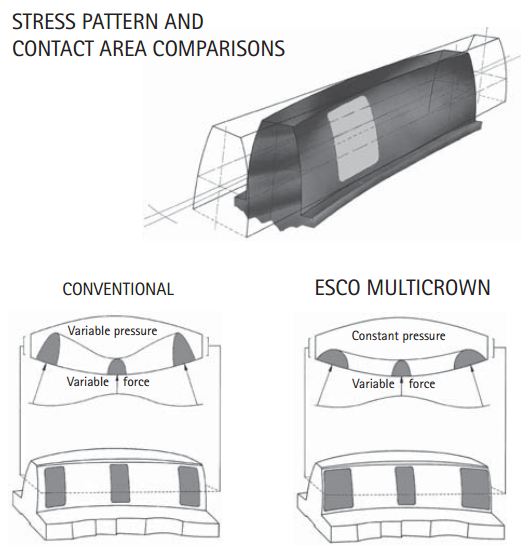

ESCO MULTICROWN TOOTH FORM FOR LONG LIFE

- LOWER STRESSESThe ESCO MULTICROWN tooth form is a curve with constantly changing radii of curvature. The tooth contact

area under misaligned conditions has a much larger radiusof curvature than conventional crowning. The contact area

therefore is larger thus reducing the surface stresses.

- CONSTANT VELOCITY POWER TRANSMISSION

ESCO generates the ESCO MULTICROWN, tooth in such a way that the necessary characteristics for homocinetic conjugate

tooth action are perfectly achieved.

- LESS BACKLASH

The ESCO MULTICROWN tooth design requires less backlash

for a given angle of misalignment than the conventional

crowning, thus reducing shocks in reversing ap pli ca tion.

The teeth of hub and sleeve are continuously in contact with each other and have been designed with the necessary backlash to accommodate angular-, parallel- and axial misalignment within their misalignment capacity. The angular and parallel misalignment capacity is determined by the gear tooth design and is for the standard Escogear max. 1.5° degrees (2 x 0.75°) in total. The axial misalignment capacity is limited by the gear teeth length in the sleeve and can be varied (optionally).

Esco gear couplings for high torque applications. Available in variety of configuration giving flexibility for heavy duty, arduous applications.

- LOWEST torque/weight ratio. the highest torque/max. bore ratio.

- ALLOW: the combination of important angular, radial and axial misalignment, at the same time.

- ABLE: to rotate at high rotating speeds, without vibrations. to accept the largest possible assembly options to suit the design of the driver and the driven machine

Bore Capacity: 1130mm

Nominal Torque: 504kNm

Peak Torque: 1,008kNm

Applications

- SAG & Ball Mill Drives

- Conveyor drives

- Pumps

- Fans

- Elevators

- Cranes