Poona(Holset) Rubber In Compression

Poona (Holset) rubber in Compression couplings are perfect for applications where server shock loads, torsional vibration or variable speed & load applications.

Two basic version allow for shaft to shaft connection or standard SAE flywheel connection.

- Intrinsically fail safe.

- Control of torsional vibration

- Maintenance free

- Shock load protection

- Zero backlash

- Low cost

Applications

- Diesel driven pumps

- Pumps

- Variable speed drive applications.

- Generator sets

- SAG/Ball Mill drives

Fire Pump Applications

Note: Poona couplings are an intrinsically fail safe coupling, making them ideal for electric motor or diesel driven fire pumps. In the unlikely event of rubber element failure, the coupling will continue to drive the pump.

RB Series:

- Ensures continuous operation of the driveline in the unlikely event of rubber damage

- Achieves low vibratory loads in the driveline components by selection of optimum stiffness characteristics.

- With no lubrication or adjustment required, results in low running costs.

- Avoids failure of the driveline under short circuit and other transient conditions.

- Allows axial and radial misalignment between the driving and driven machines.

- Eliminates torque amplifications through pre-compression of rubber elements. The RB Coupling gives the lowest lifetime cost.

Bore Capacity: 210mm

Nominal Torque: 13.05KNm

Max. Torque: 41.0kNm

SAE Flanges Opions: 10 / 11.5 / 14 / 18 / 21 / 24

Applications:

- Generator sets

- Pump sets

- Compressors

- Wind turbines

- Metal manufacture

- Bulk handling

- Pulp and paper industry

- General purpose heavy duty industrial applications

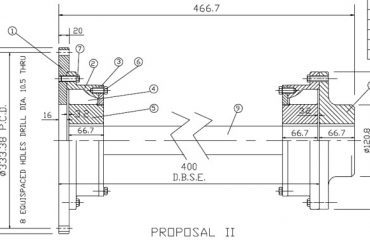

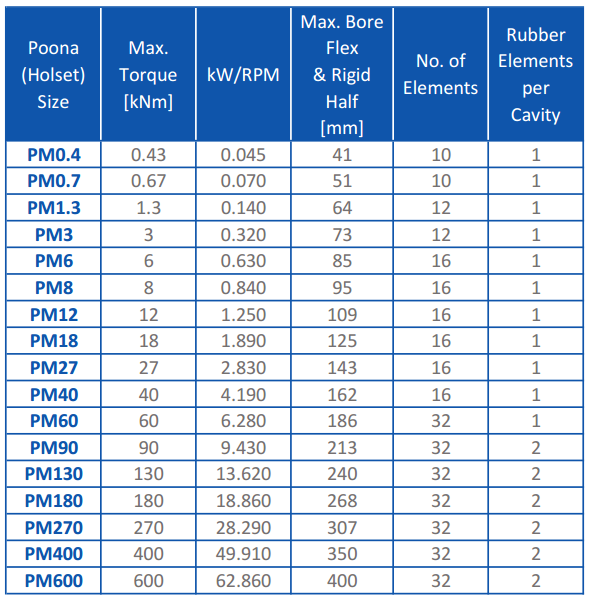

PM Series:

- Gives protection and avoids failure of the driveline under high transient torques.

- Ensures continuous operation of the driveline in the unlikely event of rubber failure or damage.

- With no lubrication or adjustment required, results in low running costs.

- Achieves low vibratory loads in the driveline components by selection of optimum stiffness characteristics.

- Eliminates torque amplifications through pre compression of the rubber elements.

- Allows axial and radial misalignment between the driving and driven machines.

- Suited for server shock loads

Max Torque: 600kNm

Applications:

- Metal manufacture

- Mining and mineral processing(Ball & SAG Mills)

- Pumps

- Fans

- Compressors

- Cranes and hoists

- Pulp and paper industry

- General heavy duty industrial applications

File attachments

| File name | Uploaded | Size |

|---|---|---|

| Drive Systems_Poona PM Couplings | 23/03/2022 | 6.67 MB |

| Drive Systems_Poona RB Couplings | 23/03/2022 | 6.38 MB |

| Drive Systems_PM Installation Manual | 29/01/2023 | 809.48 KB |